All the Parts You Need: Pumps, Controllers, Valves & Heat Exchangers

A solar water heating system is more than just collectors and a tank. The pumps, controllers, valves, and heat exchangers form the circulatory system that moves heat from your roof to your faucet. Get these solar water heater components right, and you’ll enjoy decades of reliable hot water. Choose poorly, and you’ll face leaks, inefficiency, and costly service calls.

This guide unpacks every key part—how it works, how to size it, what codes require, and what typical systems cost. Whether you’re planning a DIY install or vetting a contractor’s quote, you’ll leave with the knowledge to build or buy a system that performs year after year.

What you’ll learn:

- Which pump type matches your climate and system architecture.

- How differential controllers save energy and protect against freeze damage.

- The valves required by code and the ones that prevent scalding.

- Heat exchanger designs and their impact on collector efficiency.

- Real-world pricing, warranties, and maintenance timelines.

Let’s dive into the hardware that keeps solar hot water flowing.

🔧 Solar Water Heater Components at a Glance

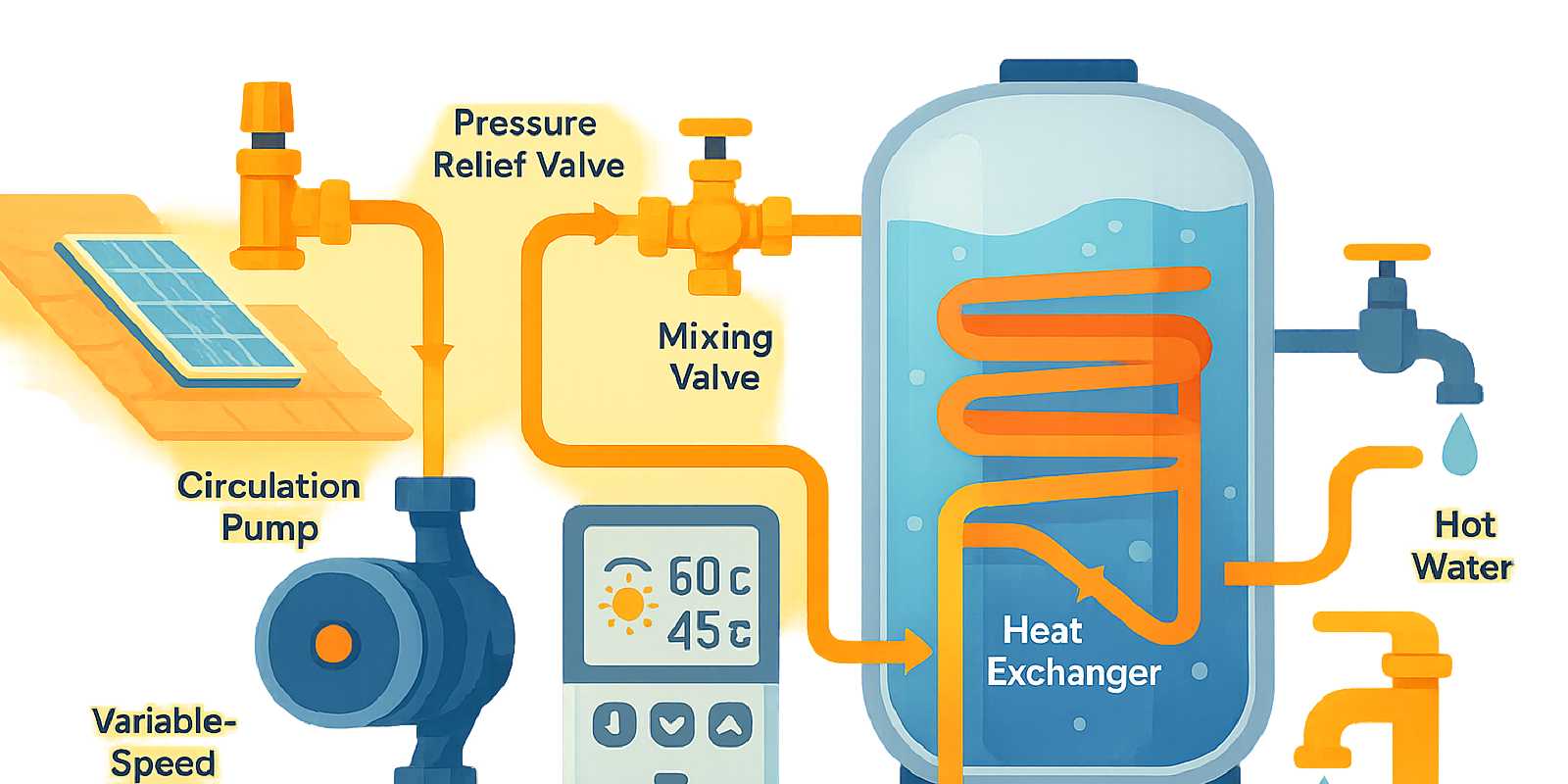

Every active solar water heating system relies on four core component groups working in concert:

Pumps circulate fluid through the collector loop. In active systems, solar water heating pumps move water or glycol from the tank to the collectors and back, ensuring continuous heat transfer. Passive thermosiphon systems skip the pump entirely, relying on gravity.

Controllers act as the brain. A solar hot water controller monitors temperature sensors and activates the pump only when the collector is hotter than the tank, maximizing energy harvest and preventing freeze damage.

Valves provide safety and flow control. Pressure relief valves prevent tank rupture; check valves stop reverse flow; mixing valves blend hot solar water with cold to prevent scalding. Each valve serves a code-mandated or performance-critical role.

Heat exchangers isolate the collector loop from potable water. In indirect systems, a solar heat exchanger transfers heat from antifreeze fluid to the tank water without mixing the two, essential for freeze protection and water quality.

Understanding how these parts interact helps you diagnose problems, optimize performance, and ensure code compliance. The table below summarizes typical system configurations:

| System Type | Pump | Controller | Heat Exchanger | Primary Valves |

|---|---|---|---|---|

| Passive ICS | ❌ | ❌ | ❌ | P/T relief |

| Direct active | ✅ | ✅ | ❌ | P/T, check, mix |

| Indirect glycol | ✅ | ✅ | ✅ | P/T, check, mix, expansion |

Each component contributes to efficiency, safety, and longevity. Skimping on quality or mismatching parts can sabotage an otherwise well-designed system.

💧 Pumps: Types, Sizing & Efficiency

The solar water heater pump is your system’s workhorse. Its job is to move fluid through collectors at the right flow rate to capture heat without wasting electricity.

Circulator Pumps vs Recirculation Pumps

Active systems typically use a circulator pump that moves fluid through the closed collector loop. This is distinct from a solar hot water recirculating pump used in some homes to keep hot water instantly available at distant taps. For solar thermal applications, you want a low-wattage circulator rated for continuous duty and high-temperature glycol or water.

Sizing the Pump

According to 2024–2025 manufacturer guidelines, pump flow rate should deliver approximately 0.4 to 0.8 liters per minute per square meter of collector area, or about 1 to 2 gallons per minute per 100 square feet. This flow rate maintains a temperature difference (ΔT) of roughly 10–20°F (5.5–11°C) between the collector inlet and outlet, optimizing heat transfer.

Example calculation:

- Collector area: 64 ft² (two 4×8 ft panels)

- Target flow: 1.5 GPM per 100 ft² = 0.96 GPM (round to 1 GPM)

- Required pump head: Estimate 10–15 feet of head for typical residential loop length and piping friction.

Select a pump rated for at least 1 GPM at the required head, with enough margin to handle minor restrictions. Undersized pumps reduce heat collection; oversized pumps waste electricity and create turbulence.

Fixed-Speed vs Variable-Speed

Modern variable-speed circulators adjust flow based on real-time ΔT, saving 30–50% electrical power compared to fixed-speed models. Variable-speed pumps also reduce wear, noise, and stagnation risk. Brands like SunMaxx integrate variable-speed control into their SmartMaxx Pro pump stations, which support up to 4A pump current and smart home integration.

Pump Lifespan & Maintenance

Quality circulators last 10–15 years under normal conditions, with warranties typically 2–5 years. Field studies show pump failure rates below 5% within the first decade, most often due to electrical issues or overheating rather than mechanical wear. To extend lifespan:

- Keep loop pressure stable (20–30 psi in glycol systems).

- Flush air during commissioning.

- Verify controller settings prevent dry running.

- Replace pumps proactively if noise or vibration develops.

For more on system installation, see our step-by-step guide.

🎛️ Controllers & Thermostats: Automation & Freeze Protection

A solar heater controller is the command center that decides when to pump, when to idle, and when to protect against freezing or overheating. Unlike simple timers, differential controllers use temperature sensors to operate pumps only when solar energy is available.

How Differential Controllers Work

The controller monitors two points: the collector outlet and the storage tank. When the collector temperature exceeds the tank temperature by a preset ΔT—typically 8–12°F (4–7°C)—the controller activates the pump. Once the ΔT drops below a lower threshold (often 3–5°F), the pump stops. This prevents wasted pump cycles and heat loss during cloudy periods or at night.

Energy Savings vs Manual/Timer Control

Independent studies and industry reports indicate that differential controllers deliver 10–30% energy savings over manual or time-clock operation by eliminating unnecessary pump runs. Smart controllers with IoT capabilities, such as those from SolarEdge and SunMaxx, allow remote monitoring, adaptive scheduling, and fault alerts, further improving performance and freeze protection.

Freeze & Overheat Protection

Advanced controllers offer:

- Freeze protection mode: Activates pump briefly to recirculate tank heat through collectors when temperature drops near freezing, preventing ice formation in direct systems.

- High-limit cutoff: Stops circulation if the tank reaches a maximum temperature (e.g., 160–180°F) to prevent overheating or pressure relief discharge.

- Stagnation management: In vacation or low-demand periods, controllers can limit pump cycles to prevent glycol degradation in closed-loop systems.

Thermostats & Setpoints

A solar water heater thermostat may be integrated into the controller or the backup heater. Set the solar tank’s backup element or gas burner to activate only when solar cannot meet demand—typically 10–15°F below the desired outlet temperature. This maximizes solar contribution.

Controller Lifespan & Warranties

Controllers typically last 10–15 years, with failure rates under 3% in the first decade. Warranties range from 2–5 years. Common issues include power surges, moisture ingress, or sensor faults. Use surge protectors and weatherproof enclosures.

Popular models:

- SunMaxx SmartMaxx Pro: Variable-speed pump control, 5-year warranty, supports up to 4A, smart integration.

- Delta-T Controls: Electronic sensors, preset ΔT activation, robust reliability.

- SolarEdge Home Hot Water Controller: 5-year warranty, integrates with PV systems, remote monitoring.

For cold-climate tips on freeze protection, visit our cold climate playbook.

🚰 Valves: Safety, Flow Control & Code Compliance

Valves are small but mission-critical. They prevent backflow, relieve dangerous pressure, and mix hot water to safe temperatures. Understanding which valves are required and how they function keeps your system safe and code-compliant.

Pressure Relief Valves

The temperature and pressure (T&P) relief valve—often called a solar water heater pressure relief valve—is mandated by the International Plumbing Code (IPC) and International Residential Code (IRC). It must be installed on the storage tank and set to open at 150 psi maximum pressure and 210°F maximum temperature.

The T&P valve prevents tank rupture from overpressure or runaway heating. The discharge pipe must route to a safe location (floor drain, outdoors) and remain unobstructed. Valves must be listed to ASME A112.4.1 or UL 1453 standards, and SRCC OG-300 systems require certified T&P valves.

Maintenance: Test the T&P valve annually by lifting the lever; a small discharge confirms function. Replace every 5–10 years or if corroded.

Check Valves

Check valves (also called backflow preventers) stop reverse flow in the collector loop, preventing hot water from siphoning back into collectors at night (thermosiphoning in the wrong direction). IPC Section 608.2 and SRCC OG-300 both require check valves in the collector circuit, listed to ASSE 1015 or equivalent.

Install a check valve on the return line from the collectors. Some systems use spring-loaded check valves; others use weighted flapper designs. Failure rates are low (under 5% in 10 years), but mineral buildup or corrosion can cause sticking. Flush systems annually to prevent valve clogging.

Mixing (Anti-Scald) Valves

Solar tanks can reach 140–160°F or higher on sunny days, creating a scalding risk. The IPC requires mixing valves (also called tempering or anti-scald valves) when tank temperature exceeds 120°F at the point of use. These valves blend hot solar water with cold to deliver a safe, consistent 120°F or less to fixtures.

SRCC OG-300 does not mandate mixing valves but requires systems prevent scalding. Best practice: install a thermostatic mixing valve at the tank outlet or at each fixture group. Set to 120°F for residential use; test quarterly.

Expansion Tanks & Isolation Valves

Closed-loop glycol systems need an expansion tank to accommodate fluid expansion when heated. Size the tank per manufacturer specs (typically 2–4 gallons for residential systems). Install isolation valves (ball valves) on either side of the pump and heat exchanger to allow component service without draining the entire loop.

Code Summary Table

| Valve Type | IPC/IRC Requirement | SRCC OG-300 | Typical Lifespan | Failure Rate |

|---|---|---|---|---|

| T&P relief | Max 150 psi, 210°F | Certified valve | 5–10 years | <3% |

| Check valve | Required in loop | ASSE 1015 listed | 10–15 years | <5% |

| Mixing valve | If tank > 120°F | Recommended | 10–15 years | <5% |

For detailed safety and compliance, see our safety compliance guide.

🔥 Heat Exchangers: Matching Source & Load Circuits

In indirect (closed-loop) systems, a solar heat exchanger transfers heat from the antifreeze collector loop to the potable storage tank without mixing the fluids. Choosing the right exchanger type affects efficiency, cost, and maintenance.

Heat Exchanger Types

Coil-in-tank: Copper coils submerged inside the storage tank. Heat transfer coefficient typically 300–800 W/m²·K. Simple, low-cost ($80–$250 per kW), and common in dual-coil solar tanks. Downside: lower surface area limits heat transfer, and coils can foul over time.

Plate heat exchangers: Flat plates stacked to create turbulent flow. Heat transfer coefficient 500–1,500 W/m²·K. Compact, efficient, and suitable for external mounting or retrofit. Cost: $100–$300 per kW. Requires periodic cleaning to prevent scaling.

External brazed plate exchangers: Tightly brazed metal plates deliver very high heat transfer (1,000–3,000 W/m²·K) in a compact package. Cost: $150–$400 per kW. Ideal for high-performance systems or limited space. Durable and modular, but the highest upfront cost.

Sizing the Heat Exchanger

Match the exchanger capacity to the collector output. A rule of thumb: the exchanger should handle 100–120% of peak collector thermal power to avoid bottlenecking. For example, a 30-tube collector delivering ~13 kW thermal peak needs an exchanger rated for at least 13–15 kW.

Under-sizing the heat exchanger reduces effective collector efficiency by creating large temperature gradients. Over-sizing adds cost but minimal performance gain. Consult manufacturer datasheets for flow rates and pressure drops.

Impact on Collector Efficiency

Higher heat transfer coefficients reduce temperature loss between the collector loop and the storage tank. A plate or brazed exchanger delivers more usable heat per square foot of collector than a coil-in-tank design, often improving overall system efficiency by 5–10%.

Lifespan & Maintenance

Heat exchangers typically last 15–20 years, with warranties of 5–10 years. Failure rates are low (under 3% in 15 years). Common issues:

- Corrosion in copper exchangers exposed to acidic or mineral-heavy water.

- Scaling in plate exchangers; flush with descaling solution every 3–5 years.

- Leaks at brazed joints; inspect annually.

Stainless steel heat exchangers resist corrosion better than copper, especially in hard-water areas. Choose materials compatible with your glycol type (propylene glycol is less corrosive than ethylene glycol).

For a deeper dive into system architecture, explore our passive vs active solar water heating guide.

✅ Buying & Maintenance Checklist + Typical Costs

Choosing quality solar water heater components balances upfront cost, warranty, and long-term reliability. Here’s a practical buying and maintenance roadmap.

Component Shopping Checklist

Pumps:

- ✅ Size for 0.4–0.8 L/min per m² collector area.

- ✅ Choose variable-speed models for 30–50% energy savings.

- ✅ Verify compatibility with glycol (if closed-loop) and high temperatures.

- ✅ Look for 5-year warranties; expect 10–15 year lifespan.

Controllers:

- ✅ Select differential controllers with adjustable ΔT (8–12°F typical).

- ✅ Confirm freeze and high-limit protection modes.

- ✅ Consider smart/IoT models for remote monitoring and alerts.

- ✅ Verify 2–5 year warranty; 10–15 year expected life.

Valves:

- ✅ T&P relief valve: ASME A112.4.1 or UL 1453 listed, 150 psi / 210°F.

- ✅ Check valve: ASSE 1015 listed for backflow prevention.

- ✅ Mixing valve: Thermostatic, set to 120°F.

- ✅ Expansion tank for closed-loop systems.

Heat Exchangers:

- ✅ Match type to system: coil-in-tank (low cost), plate (balanced), brazed (high efficiency).

- ✅ Size for 100–120% of peak collector output.

- ✅ Choose stainless steel in hard-water areas.

- ✅ Verify 5–10 year warranty; 15–20 year lifespan.

2025 Component Costs & Warranties

| Component | Typical Cost (USD) | Warranty | Lifespan | Failure Rate |

|---|---|---|---|---|

| Circulator pump | $150–$400 | 2–5 years | 10–15 years | <5% |

| Differential controller | $100–$300 | 2–5 years | 10–15 years | <3% |

| T&P relief valve | $20–$50 | 1 year | 5–10 years | <3% |

| Check valve | $15–$60 | 1–5 years | 10–15 years | <5% |

| Mixing valve | $50–$200 | 1–5 years | 10–15 years | <5% |

| Coil-in-tank exchanger | $80–$250/kW | 5–10 years | 15–20 years | <3% |

| Plate heat exchanger | $100–$300/kW | 5–10 years | 15–20 years | <3% |

| Brazed exchanger | $150–$400/kW | 5–10 years | 15–20 years | <3% |

Annual Maintenance Tasks

Spring:

- Clean collector glazing and check tubes.

- Test controller differential and pump activation.

- Inspect all valves for leaks or corrosion.

- Test T&P relief valve; replace if discharge continues.

Summer:

- Monitor for overheating; adjust high-limit setpoint if needed.

- Check loop pressure (glycol systems); top up if below 20 psi.

Fall:

- Test freeze protection mode (if equipped).

- Flush sediment from storage tank.

- Verify mixing valve delivers 120°F or less.

- Inspect heat exchanger for scaling; descale if necessary.

Winter:

- Confirm glycol concentration (closed-loop); replace every 3–5 years.

- Monitor pump operation during sunny days.

- Clear snow from collectors if safe.

DIY Troubleshooting Checks

Before calling a pro, verify:

- Pump not running: Check controller ΔT setting; verify sensors are secure; confirm power supply.

- Low heat output: Clean dirty collectors; bleed air from loop; verify pump flow rate.

- T&P valve dripping: Check for stagnation or high-limit cutoff failure; reduce backup setpoint.

- Check valve stuck: Flush loop; replace valve if mineral buildup persists.

For more troubleshooting steps, see our troubleshooting guide.

Linked Case Study

A real-world example: one homeowner retrofitted an existing tank with a Heliatos kit (small flat-plates + PV-powered pump). By adding a thermostatic mixing valve and upgrading the controller, they achieved a 40% annual hot water savings with minimal upkeep. Read the full story in our retrofit case study.

❓ FAQ: Getting the Best Performance from Your Parts

How do I choose between fixed-speed and variable-speed pumps?

Variable-speed pumps save 30–50% electricity and adapt flow to real-time conditions, making them ideal for most residential systems. Choose fixed-speed only if upfront cost is critical and your system is very simple.

Can I install a solar controller on an existing water heater?

Yes. Many solar hot water controllers are designed to retrofit tanks. Pair with a small pump and flat-plate collectors to preheat incoming cold water, reducing backup heater cycles. See our DIY retrofit kits guide.

What happens if I skip the mixing valve?

You risk scalding. Solar tanks can exceed 140°F on sunny days, well above safe shower temperatures. Mixing valves are required by code when tank temps exceed 120°F and protect your family from burns.

How often should I replace the glycol in a closed-loop system?

Test glycol pH and freeze point every 3 years. Replace when pH drops below 7.5 or freeze protection degrades. Typical replacement interval: 3–5 years.

Do I need a professional to install these components?

Installation complexity varies. Pumps and controllers are DIY-friendly for handy homeowners; heat exchangers and code-compliant valve installations may require licensed plumbers. Always follow local codes and get permits. Our step-by-step install guide covers the full process.

What’s the most common component failure?

Pumps and controllers have the highest replacement rates, though still under 5% in 10 years. Use quality parts, install surge protectors, and perform annual inspections to minimize failures.

Can I use a standard water heater thermostat for solar?

No. Solar systems require a differential controller that compares collector and tank temperatures. Standard thermostats only measure tank temperature and won’t optimize solar energy harvest.

How do I know if my heat exchanger is undersized?

If your tank never reaches full solar temperature on sunny days, or if the collector outlet temperature is much higher than the tank, your exchanger may be bottlenecking. Verify the exchanger is rated for your collector’s peak thermal output.

Related Articles

- Passive vs Active Solar Water Heating: Which One Fits Your Home?

- Step-by-Step: Installing a Residential Solar Water Heating System

- Cold Climate Playbook: Glycol Loops, Drainback & Insulation

- Safety & Compliance: Valves, Mixers, Temperatures & Codes

- Troubleshooting Guide: Not Hot Enough, Pump Stuck, Freeze Damage